Non-destructive evaluation is crucial during asset inspection, as many defects cannot be seen on the surface. However, getting high-quality data at critical locations is challenging for asset operators and inspection workers alike.

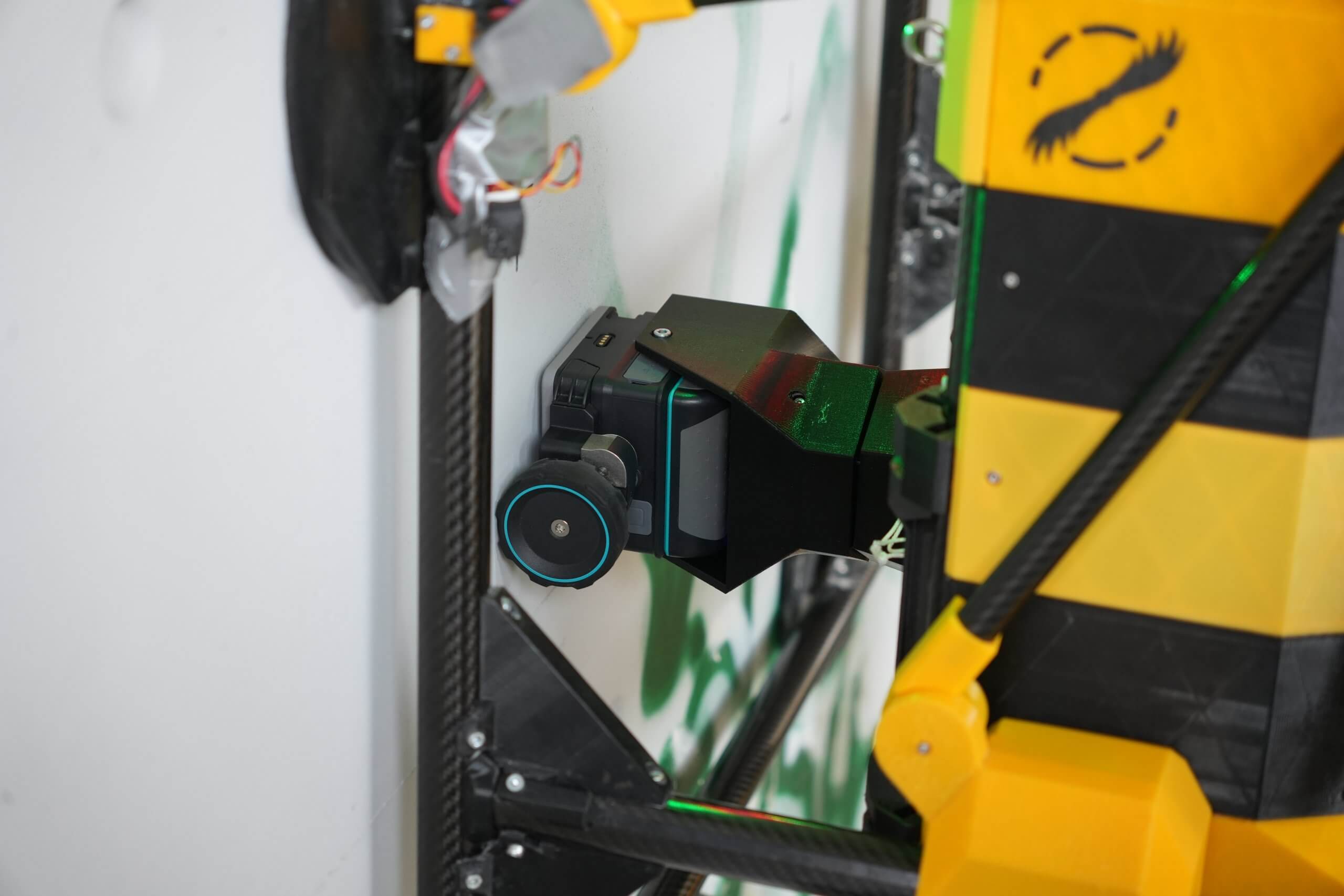

By using state-of-the-art methods and having full interaction capability, compromising on data quality due to limited access is a thing of the past. On our platform we can deploy common NDE payloads including ground-penetrating radar (GPR) and various types of ultrasonic tomography (UT).

The mission in short

On a highway bridge, GPR and UT data was collected at the same location. This combination simplified interpretation, as each method has unique advantages. On the Aithon drone, state-of-the-art sensor payloads were used to collect the highest possible data.

For ground-penetrating radar, area-scans were performed, giving 3D information on the location of objects up to a depth of 65 cm. Aithon allows for high-precision repeatability of passes until sufficient data quality is collected. The same goes for ultrasonic tomography, which can penetrate deeper and is ideal for the detection of cracks, inhomogeneties and delaminations.

As a result, the combination allows for the localization of wanted and unwanted features within infrastructure, either to investigate the asset condition or as a preparation step for further work.

Frequently asked questions for drone-based NDE

What NDE payloads do you offer?

Ground-penetrating radar and ultrasonic tomography are two of the most capable methods, but Aithon can also perform rebar localization and marking on-site.

In principle however, many different payloads can be adapted to work, get in touch if you have a particular tool you want to use!

What are the advantages of using Aithon to collect NDE data?

By decoupling flight from interaction, a tool positioning system can ensure mm-level accuracy when collecting data. Further, area-covering scans can be done, with any level of resolution and with as many passes as needed.

Further, by using state-of-the-art sensor payloads, the post-processing of data can be done exactly the same way as with human data collection – saving time and money!

How does NDE improve asset understanding and operations?

Non-destructive evalution is the second step of asset inspection, after visual inspection. The most significant advantage is the ability to see inside the material, as this is where many issues can be caught before they are seen on the surface.

High-performance tools can provide high-accuracy information in three dimensions, and with Aithon multiple data sources can be combined to maximize the benefit of each.