Asset monitoring is essential to ensure the safety and reliability of aging infrastructure, by providing real-time information on the behaviour and condition of an asset.

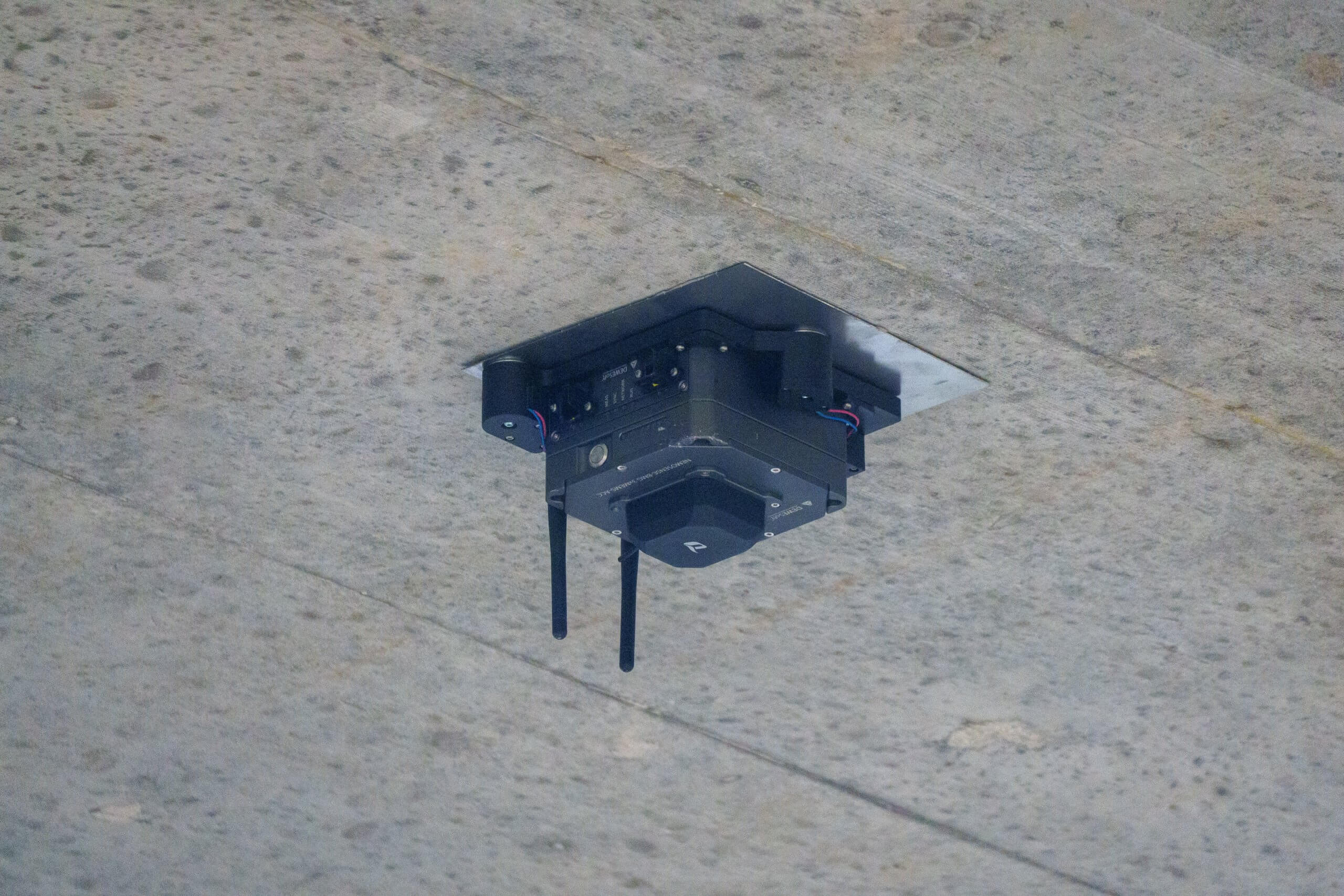

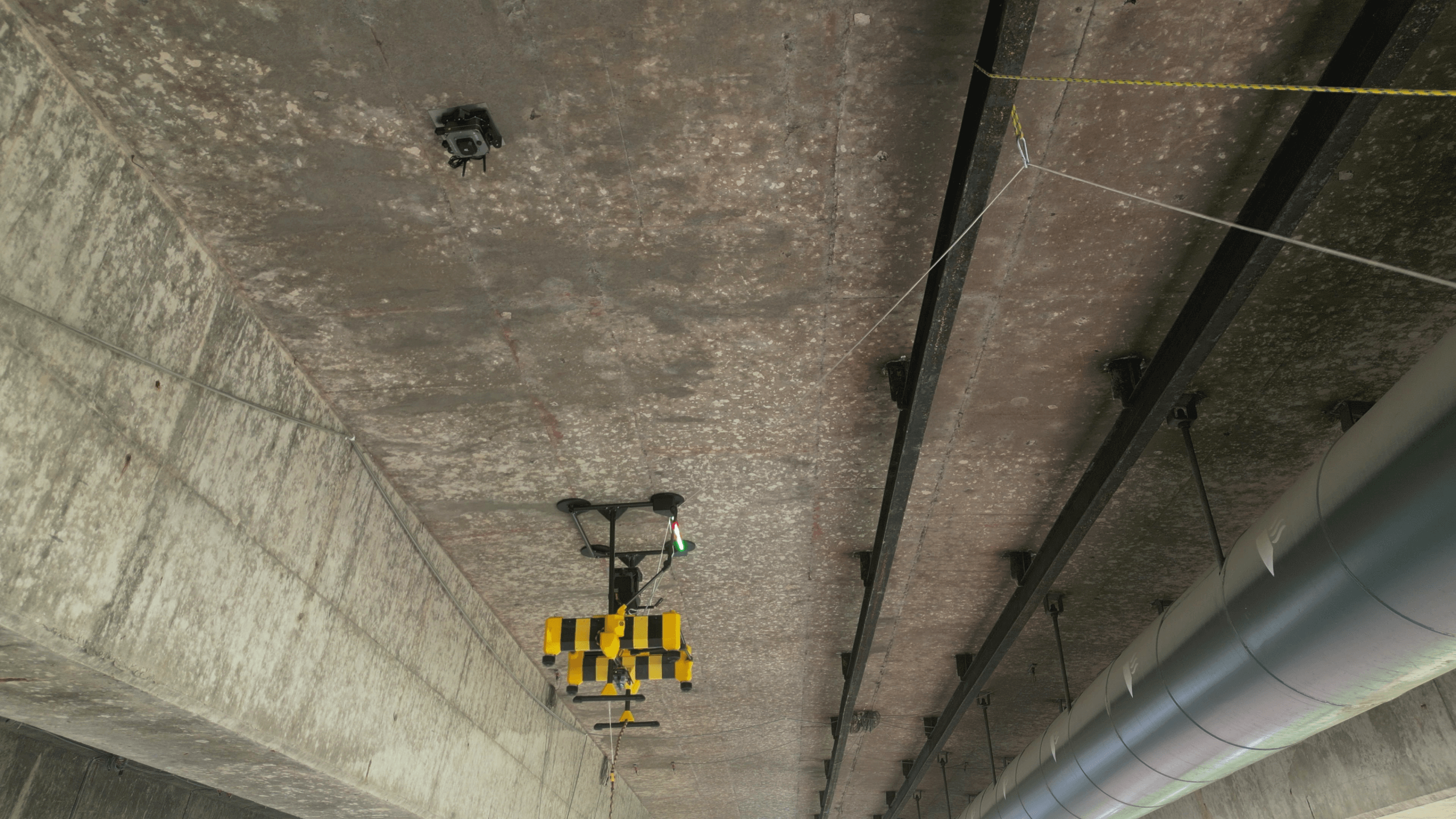

Traditionally, this has required dangerous manual access via rope teams or snooper trucks to install and maintain IoT devices. With Aithon, this work can be done with minimal asset downtime and high flexibility for many types of sensors.

Mission results

Cost Savings

The mission was performed with 75% less manhours and without any fees for lane closure or traffic impact.

Zero lane closures

During the entire mission, the traffic was not slowed down due to installations.

High-precision placement

On the soffit, sensors can be placed without considering other factors – maximizing data quality while minimizing the impact on nominal operations.

Frequently asked questions for drone-based sensor installations

What sensors can be installed?

Any sensor up to 2.5kg in weight can be installed, this includes structural health monitoring (e.g. accelerations, deflections), environmental (e.g. temperature, humidity) or local (e.g. crack-meter) installations.

In most cases, these sensors can be installed adhesively or magnetically, ensuring the asset is not damaged.

What are the advantages of using Aithon for monitoring deployments?

We provide a more flexible and safer access solution. This results in minimal asset downtime and increased operational efficiency, as well as saving costs directly by typically requiring less manhours and less expensive equipment.

From a monitoring perspective, we can optimize the location of sensors to get better data with less sensors.

What happens if a sensor breaks down or needs to be replaced?

Depending on the sensor and installation method, the sensor can be replaced easily. This is in particular useful for short-term monitoring of less than a week, where we can reposition sensors along an asset based on your needs.